I’m currently evaluating the Ruger Super Blackhawk Bisley in 480 Ruger for an everything but hunting review. Most reviews on this particular gun are similarly narrow in scope so I hope to bring you something different by the end of the year.

I’m currently evaluating the Ruger Super Blackhawk Bisley in 480 Ruger for an everything but hunting review. Most reviews on this particular gun are similarly narrow in scope so I hope to bring you something different by the end of the year.

My introduction to bullet casting began with the need for a particular bullet comprised of a specific alloy. I had begun loading 32-20 with black powder to shoot out of my Uberti SAA clone (review here). Before jumping in with both feet I purchased bullets cast in the Lyman mold, 311008, by a reputable company. The particular samples purchased were relatively soft, around 8 Bhn, and lubed with SPG, a common black powder compatible lubricant. The bullets arrived pre-sized to .313″ which is what I needed at the time. While they worked great they were prohibitively expensive.

My best option was to purchase the mold and make my own bullets with the alloy I could scrounge at my local range. Now, a bit of education for the novice: Generally speaking, Lyman bullet molds list the nominal bullet diameter in the preface of the numerical indicator. So a 311xxx will cast no larger than .311″. To top it off Lyman recommends the use of their #2 alloy for all casting. For those not in the know #2 alloy is quite a bit harder than the softer alloys typically encountered with black powder shooting. Think Bhn 15 or thereabouts. Bhn 15 is double the hardness that I would need. And seeing as how this particular mold was designed for a cartridge introduced in 1882 it seems likely that it would probably obtain the nominal diameters without the need for harder lead alloys.

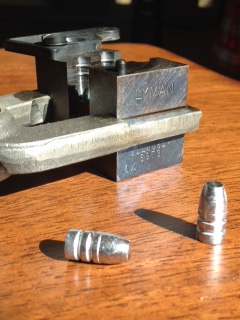

And that’s where I made one of many first mistakes in bullet casting. After acquiring a suitable bottom-pour casting furnace I bought the Lyman 311008 and handles for around $140 all together. That’s not including the equipment to size and lube the bullets but I will not go into those expenses for this review. I then collected a small assortment of fired bullets and fragments of those bullets known colloquially as range scrap. I melted them down into ingots to remove impurities and then cast bullets from the ingots with my new mold.

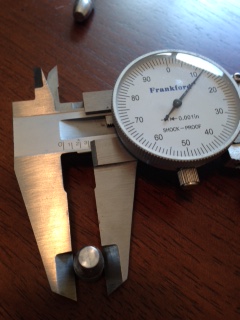

So what was the result? A bullet that never reached more than .310″ of course. Range scrap has a Bhn of around 9-10 give or take. That’s quite at bit less than the recommended #2 hardness. But the store bought bullets? Yeah, it makes no sense. They must have had a modified mold or an older mold which are known the cast larger diameters. I tried casting barely hot, hotter, and frosted bullet hot. It didn’t matter. They all came out undersized. I lubed and loaded them up anyways. Accuracy wasn’t abysmal but it wasn’t as great as the store bought fodder either.

To keep this from getting too long I solved the problem by buying a different mold, the RCBS 32-098-SWC. It casts a beautiful bullet more akin to a round nose flatpoint than a true semi-wadcutter. It also casts a nominal diameter of .313″ with any alloy. And coming in at 100 grains as opposed to the 115 grains of the Lyman, it was easy to find suitable load data in that particular bullet weight range.

As to the Lyman 311008 – I still have the mold. After a few years of casting I tried it with a custom alloy consisting of one part Linotype to three parts of range scrap. It gives an approximate hardness of Bhn 11.4, still a bit less than the #2 alloy but it drops from the mold at .312″ so I’ll take what I can get. I currently use the bullet for high velocity smokeless loads in my SAA clone. The one saving grace for this mold is that it produces accurate bullets when cast with harder alloys.

Lyman 311008 bullets cast of 1:3 Lino to Range Scrap produced an acceptable bullet for high velocity smokeless loads.

Moral of the story: Don’t let your initial bullet casting experiences sway you from pursuing a time honored and truly enjoyable side hobby. I almost wrote off bullet casting for good if not for other mold manufacturers. And there are much better molds than Lyman. While they still catalog some classic designs there are much better molds out there for the beginning caster. I’ve used RCBS, Lee, and Accurate with RCBS comprising the majority of my collection. If you want to start casting bullets maybe don’t start with Lyman molds. They’re not cheap and from what I’ve learned from other reviews their problems with casting undersized bullets has not been limited to my experiences. If anything I hope my fourteen nickels worth of free advice has been useful.